佐世保の街金!ブラックでも借りれるカードローンとは。

激甘審査でブラックでも借りれる街金、おすすめ17社。

審査が驚くほど甘い街金が多く、急な資金が必要な時に助けになると注目されています。

しかし、審査が甘いということは、裏を返せばリスクも伴うのではないかと不安に思う方も多いでしょう。

果たして、本当に安心して利用できるのでしょうか?

この記事では、激甘審査のカードローンの実態や、どんな人がどのように利用しているのかを徹底解説します。

また、利用時の注意点や、金利や返済条件などの重要な情報についても触れています。

この記事を読むことで、カードローンを利用する際に知っておくべき情報や、どのように選べばより有利になるかがわかります。

安全に活用するためのポイントを押さえることができるので、無駄なトラブルを避けるために役立ちます。

- 佐世保の街金!ブラックでも借りれるカードローンおすすめ一覧

- 1.クレジットカード現金化【プライムウォレット】選ばれ続ける超優良店

- 2.クレジットカード現金化【インパクト】最短5分で振込完了

- 3.クレジットカード現金化【あんしんクレジット】業界最高クラスの還元率

- 4.クレジットカード現金化【Quick現金サービス】とにかく早い!

- 5.クレジットカード現金化【どんなときもクレジット】初めての方、換金率3%UP

- 【QUICK39】お金を貸してくれるところをご紹介

- 1.【フクホー】ゆとりのローン!安心の金利7.30%〜

- 2.【スカイオフィスキャッシング】スピードと信頼の消費者金融

- 3.【キャレント】で借りんと!融資申込みキャンペーン中!

- 4.【アロー】最短即日融資もOK

- 5.【アルコシステム】信頼と実績のキャッシング

- 6.【プラン】全国どこからでも24時間簡単ご契約

- 7.【クレジットのニチデン】簡単・便利なネットキャッシング

- 8.【いつも】いつものキャッシング

- 9.借りやすくて返しやすい!キャッシング【フタバ】

- 10.来店不要・振込キャッシング【パーソナルクレジット セントラル】

- 11.安心できるパートナー【ハローハッピー】フリーローン

- 12.来店不要・振込キャッシング【女性専用 マイレディス】

- 女性専用!在宅で稼ぐ【FANZAノンアダルトチャットレディ募集】

- 佐世保の街金|サービス対象地域について

- 佐世保の街金!ブラックでも借りれるカードローンを探すときの注意点

- 佐世保の街金!ブラックでも借りれるカードローンは審査が甘い

- 佐世保の街金!ブラックでも借りれるカードローン|総量規制オーバーでも借りれるか?

- 佐世保の街金!ブラックでも借りれるカードローン|即日融資を受けるには

- 佐世保の街金!ブラックでも借りれるカードローン|闇金との違い

- 佐世保の街金!ブラックでも借りれるカードローンで審査落ち・・お金を借りれないときは

佐世保の街金!ブラックでも借りれるカードローンおすすめ一覧

かんたんアンケートに答えるだけで、おこづかいをゲット

| 無料会員登録!アンケートに参加するだけで、お小遣い稼ぎ |

|||

| サービス名 | サービス内容 | 報酬額 | 無料登録 |

| 【マクロミル】 |

スマホやPCで手軽にアンケートに答えて「現金」や「電子ギフト券」に交換可能なポイントがもらえます! | 新規登録で最大1000ポイント!(1,000円相当) | \会員120万人/ |

【オピニオンワールド】 |

かんたん登録1分、会員登録無料!ポイントを現金かギフトカードに交換 | アンケート1回につき、最高900円! | \900円ゲット/ |

【ボイスノート」】 |

かんたん登録1分、アンケート参加でポイントを現金かギフトカードに交換 | 会員登録だけで70ポイント獲得! | \今すぐ登録/ |

【モニタータウン |

かんたん登録1分、設定5分、会員登録無料!現金かギフトカードに交換 | アプリインストールでポイント獲得(2,800円相当) | \iphone専用/ |

【モニタータウン |

かんたん登録1分、設定5分、会員登録無料!現金かギフトカードに交換 | アプリインストールでポイント獲得(2,800円相当) | \Android専用/ |

【モニタータウン】 |

かんたん登録1分、設定5分、会員登録無料!現金かギフトカードに交換 | アプリインストールでポイント獲得(900円相当) | \PC専用/ |

【ハピタス】  |

お買い物やサービスの申し込みでポイントを貯めて、現金やギフト券に交換 | 会員登録時・500ptをプレゼント | \会員80万人/ |

スマホと紹介コードが必須!

スマホで銀行口座を開設するだけでおこづかいゲット!

| かんたん!【スマホ専用】無料の銀行口座開設でお小遣いをゲット | |||

| 銀行名 | 報酬額 | 紹介コード | 無料口座開設(スマホ必須) |

第一生命NEOBANK |

¥1,500 | oFFWZrM | 第一生命NEOBANK |

みんなの銀行 |

¥500 | hYBchqNL | みんなの銀行 |

UI銀行 |

¥500 | sh4402 | UI銀行 |

女性限定のお金稼ぎ!

在宅OKのかんたん美容モニタや、チャットレディ

| 【女性限定】かんたん!即金!お小遣い稼ぎができる在宅ワーク | |

【女性専用!美容モニター】 |

エステだけでなく、コスメや健康食品などを試せる在宅ワークのモニターも多数!「ファンモニ」(無料)会員登録はこちら 謝礼は1件1000円~5,000円ほど、複数組合わせれば月4万円以上も可能 |

【女性専用!在宅で稼ぐ】 |

自分の好きなタイミングで稼げるFANZAの在宅チャットレディ! ノンアダルトだから安心!スマホでかんたん在宅ワーク 時給7,500円以上可、安心の個人情報対策、最短翌日振込! |

ファクタリングなら!

あなたの持っている債権を買取ります!

| ファクタリング | 即日融資 | 手数料 | 申込み |

1.アクセルファクター |

来店不要 最短2時間!即日融資 |

買取手数料0.5%~ 審査通過率 93.3%以上 |

\個人・法人/ |

2.資金調達プロ |

かんたん10秒! 無料診断 最短即日融資 |

提携事業者数No1! 資金繰り改善率93%以上 |

\個人・法人/ |

3.株式会社No.1 |

最短30分で即日振込可能 | 買取手数料1%~(業界最安) 審査通過率 90%以上 |

\個人・法人/ |

4.エスコム |

最短即日で審査完了。 即日に資金調達可能。 |

1.5%〜12% 資金化成功率97% |

\個人・法人/ |

5.Easy factor |

最短10分でお見積り 最短60分で振込可能 |

2%〜8% 資金化成功率97% |

\個人・法人/ |

6.いーばんく |

来店不要 最短即日入金可能 |

買取手数料4%~ 審査通過率 90%以上 |

\個人・法人/ |

7.ジャパンマネジメント |

最短即日で審査完了。 翌日に資金調達可能。 |

三社間(3%~10%) 二社間(10%~20%) 資金化成功率93% |

\個人・法人/ |

8.PayToday |

最短30分で審査完了。最短45分で振込可能。 | 1%〜9.5%(上限) | \個人・法人/ |

9.MSFJ |

来店不要 最短1日で買取可能 |

1.8%〜9.8% 累積実績1万件以上 |

\個人・法人/ |

10.トラストゲートウェイ |

来店不要 最短即日振込 |

1.5%〜9.5%(業界最安水準) 審査通過率95% |

\個人・法人/ |

11.トップ・マネジメント |

来店不要 最短即日振込 |

3社間ファクタリング(買取対象債権の99.5%〜96.5%) 2社間ファクタリング(買取対象債権の96.5%〜87.5%) |

\個人・法人/ |

12.西日本ファクター |

最短即日即買取り 診断無料 |

【九州、中国、四国エリアに限定】 手数料は2.8%〜 |

個人・法人(九州、中国、四国) |

13.三共サービス |

来店不要 資金化まで最短翌日 |

平均手数料8% 資金化成功率97% |

\法人のみ/ |

14.ネクストワン |

来店不要 資金化まで最短即日 |

1.5%〜10%(業界最安水準) | \法人のみ/ |

15.ラボル |

来店不要 最短30分入金 |

買取額の10% 振込手数料などの費用なし |

\個人事業主のみ/ |

16.請求書先払い |

最短60分でお振込み 対面不要 |

手数料3%〜10% 最低買取金額10万円 |

\個人事業主のみ/ |

クレカの現金化サービスなら、即日にも対応してくれます!

| 社名 | 即日融資 | 実質年率 | 限度額 | 特徴 |

1.クレカ現金化「プライムウォレット」 |

最短10分 | 還元率最大98% | 設定なし | ・24時間受付 ・土日祝日も即日振込 ・カード事故過去0件 |

2.クレカ現金化「インパクト」 |

最短5分 | 還元率最大99.5% | 設定なし | ・審査不要 ・土日祝日も即日振込 ・来店不要 |

3.クレカ現金化「あんしんクレジット」 |

最短3分 |

還元率最大99.5% |

設定なし | ・審査不要 ・土日祝日も即日振込 ・来店不要 |

4.クレカ現金化「Quick現金サービス」 |

最短20分 | 還元率最大90%(手数料無料) | 設定なし | ・24時間365日受付 ・土日祝日も即日振込 ・審査不要 |

5.クレカ現金化「どんなときもクレジット」 |

最短5分 | 還元率最大98% | 設定なし | ・24時間受付 ・土日祝日も即日振込 ・スマホで申込完結 |

QUICK39のキャッシングローン紹介 |

お金を貸してくれるトコロを見つけます。 どこからも借りれない・・金利が高くもっと安いところへ借り換えしたい・・こんな悩みを解消します。 |

・完全無料 ・紹介料無料 ・手数料無料 |

||

1.フクホー |

対応 | 7.3%〜18.0% | 1〜200万円 | ・24時間受付 ・来店不要 ・利息は利用日数分だけ |

2.スカイオフィスキャッシング |

対応 | 15.0%〜20.0% | 1〜50万円 | ・24時間受付 ・来店不要 ・最短30分で審査完了 |

3.キャレント |

対応 ※ | 7.8%〜18.0% | 1万円~500万円 | ・24時間受付 ・来店不要 ・申込まで3分で完了 |

4.アロー |

対応 | 15.0%〜19.94% | 200万円まで | ・24時間受付 ・来店不要 ・かんたん3秒診断 |

5.アルコシステム |

対応 | 15.0%〜20.0% | 1〜50万円 | ・24時間受付 ・来店不要 ・保証人・担保不要 |

6.プラン |

対応 | 12.00%~18.00% | 1〜50万円 | ・24時間受付 ・来店不要 ・保証人・担保不要 |

7.クレジットのニチデン |

対応 ※ | 7.3%〜17.52% | 1〜50万円 | ・24時間受付 ・来店不要 ・100日間利息なし(初回のみ) |

8.いつも |

対応 | 4.8%~18.0% | 1万円~500万円 | ・24時間受付 ・来店不要 ・最大60日間利息なし(初回のみ) |

9.フタバ |

対応 | 14.959%~19.945% | 1万円~50万円 | |

10.セントラル |

対応 |

4.8%~18.0% |

1万円~300万円 | ・24時間受付 ・最大30日間利息なし(初回のみ) ・セブン銀行ATMでご利用ご返済が可能 |

11.ハローハッピー |

対応 | 10.00%~18.00% | 100万円まで | ・24時間受付 ・来店不要 ・保証人・担保不要 ・パート・アルバイト・主婦の方も歓迎 |

12.マイレディス |

対応 | 4.80%〜18.00% | 1万円〜100万円 | ・24時間受付 ・来店不要 ・保証人・担保不要 ・女性専用キャッシング |

【女性専用!在宅で稼ぐ】 |

自分の好きなタイミングで稼げるFANZAの在宅チャットレディ! ノンアダルトだから安心!スマホでかんたん在宅ワーク 時給7,500円以上可、安心の個人情報対策、最短翌日振込! |

|||

13.オージェイ |

対応 | 9.5%〜18.0% | 10万円~5,000万円 | ・24時間受付 ・来店不要 |

14.アクト・ウィル |

対応 | 7.5%〜15.0% | 300万円~1億万円 | ・24時間受付 ・来店不要 ・審査は最短60分 |

15.ファンドワン |

対応 | 2.5%〜18.0% | 30万円~1億円 | ・24時間受付 ・来店不要 ・審査は最短40分 |

16.MRF |

対応 | 4%〜15.0% | 30万円~3億円 | ・24時間受付 ・来店不要 ・24時間以内に仮審査 |

※ 平日14時までの手続完了が条件

激甘審査の絶対すぐ借りれる街金(消費者金融)をご紹介します。

どの消費者金融も独自審査を採用しており、柔軟な対応をしてくれるのでブラックでも借りれて即日融資OKの可能性が高いです。

ブラックだからと諦めずに真剣にお金が必要な理由を説明して少しでも融資をしてもらえる確率をあげましょう。

またクレジットカードを現金化してくれる優良サービス店も合わせてご紹介します。

1.クレジットカード現金化【プライムウォレット】選ばれ続ける超優良店

ショッピング枠現金化業界で超有名で誰もが知っているプライムウォレット!

現在日本でも、キャッシュレス化が進んでおりクレジットカードを保有する方は増えておりますね♪

15時以降でも即日振込み可能で、地方銀行もOKです。

2.クレジットカード現金化【インパクト】最短5分で振込完了

インパクトは、超高還元率(最高99.5%)でしられるクレジットカード現金化優良店です。

さらに新規申込で2%換金率UP!

審査不要、来店不要で最短5分でお振込み。

クレジットカードのショッピング枠があれば現金化してくれる安心の優良店です。

3.クレジットカード現金化【あんしんクレジット】業界最高クラスの還元率

あんしんクレジットは、超高還元率(最高98.8%)でしられるクレジットカード現金化優良店です。

審査不要、来店不要で最短5分でお振込み。

クレジットカードのショッピング枠があれば現金化してくれる安心の優良店です。

4.クレジットカード現金化【Quick現金サービス】とにかく早い!

Quick現金サービスは、振込金額を最初に提示する優良現金化サービスです。

24時間WEB対応やLINEチャットなど、お客様目線のサービスを提供し続けてリピーターは脅威の90%以上!

急な出費でお金が足りない!そんな方でも大丈夫!

5.クレジットカード現金化【どんなときもクレジット】初めての方、換金率3%UP

急な出費で困っていませんか?

どんなお悩みも、どんなときもクレジットにお任せください。

お申込みが初めての方なら換金率3%アップ!

審査不要、来店不要で今すぐ現金化してくれる安心サービスです。

【QUICK39】お金を貸してくれるところをご紹介

消費者金融からの借り入れが多数あってどこからも借りれないと思っている方や 金利が高くてもっと安いところへ借り換えしたい方・・・

このような悩みを抱えたお客様にたいして 安心して安全でより安く借り入れが出来るようにサポートさせていただいております。

完全無料ですのでお客様から紹介料・手数料等の料金は一切いただいておりません。

1.【フクホー】ゆとりのローン!安心の金利7.30%〜

★創業45年★

キャッシング・消費者金融のフクホー 安心の金利7.30%〜!

最高200万円までのゆとりのローン。

キャッシング・消費者金融・ローンなら創業45年のフクホー。

ご来店一切不要、振込み キャッシングの消費者金融です。

レディースキャッシングもご用意しているので、女性の方でも安心してご利用頂けます。

2.【スカイオフィスキャッシング】スピードと信頼の消費者金融

最短30分!来店不要 スピードキャッシング!!受付は24時間可能!

当日 9:00〜14:00 までにお申込み頂きますと、 即日のお振込みが可能です。

スカイオフィスニッセイキャッシングは他社で断られた方でも柔軟に対応している消費者金融です。

インターネットから申込みを行い、審査が完了すればその日に融資を受けられます。

来店不要のスピードキャッシングは急な出費でお困りの方の力強い味方です。

3.【キャレント】で借りんと!融資申込みキャンペーン中!

インターネット専用キャッシング♪完全非対面でネット完結。

カード発行不要!全国どこでもご指定の銀行口座にお振込み致します。

担保、保証人不要でキャッシングが可能です。

インターネット申込み、365日、24時間受付中!

申込フォームの入力内容が少なく、簡単にお手続きいただけます♪

ご利用限度額は【1万円〜500万円】まで。

大手消費者金融、カードローンの審査が通らなかった方でも柔軟な審査で対応致します。

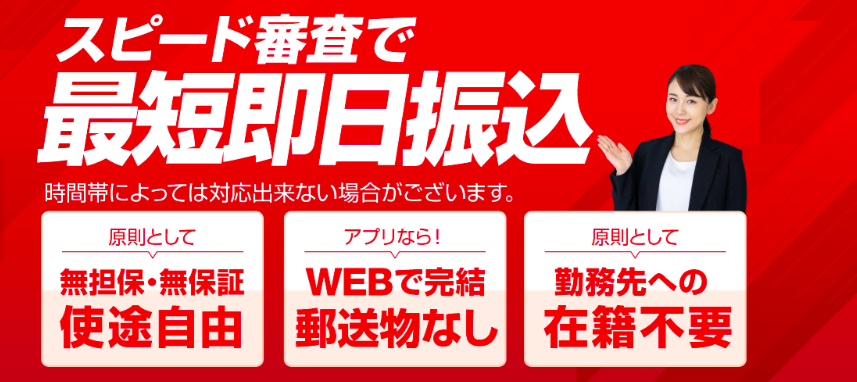

4.【アロー】最短即日融資もOK

無担保かつスピーディーな使途自由ローンです。

・独自審査

・来店不要

・最短即日振込

・アプリならWEBで完結、郵送物は一切なし!

「郵送物が一切不要なアローWEB完結ローン」の取扱いを開始いたしました。

お申込み後、一次審査が通過した方は、スマホでアプリをダウウンロードして頂くことで、 サービスをご利用いただくことができます。

5.【アルコシステム】信頼と実績のキャッシング

創業1983年、信頼と実積、振込キャッシングの老舗です。

お申し込み後、最短でその日のうちにご指定口座に送金いたします。

貸付利率(実質年率) 年3.00%~20.00%

保証人・担保不要。

ご融資範囲 50万円まで(要審査)

お申し込みはWEBで、24時間受付中。

6.【プラン】全国どこからでも24時間簡単ご契約

全国どこからでも24時間ネットでお申し込みからご契約まで可能です。

又、キャッシュサービス『プラン』では1万円から最高50万円までご融資可能です。

・ご来店不要

・最短即日ご融資可能

・担保・保証人不要

・月々2,000円からのご返済も可能

7.【クレジットのニチデン】簡単・便利なネットキャッシング

簡単・便利・ネットキャッシング ニチデンのネットキャッシングへようこそ。

簡単・便利・ネットキャッシング ニチデンのネットキャッシングへようこそ。

振込ローン・不動産担保ローン・事業者ローンをご用意しています。

学生ローンにも対応、20歳以上で定期的に収入のある方を対象としております(パート・アルバイト・主婦の方も歓迎します)

大学生〜幅広い層に対応しており、福山、福山と3店舗ありますので手厚いサービスをモットーとして運営しています。

8.【いつも】いつものキャッシング

『早い』 来店不要!24時間申込受付、最短45分でお振込完了。

『頼れる』ご利用は1万円〜最大500万円まで。

『便利』 カード発行不要!郵送物一切なし!お客さまに合わせた柔軟な在籍確認。

『安心』 LINEやメール・電話でご対応、ご融資まで完全サポート。

『納得』 電話応対コンクールにて数度入賞した丁寧なご対応。

9.借りやすくて返しやすい!キャッシング【フタバ】

創業50年以上の実績と信頼のキャッシングのフタバです。

・来店不要・即日振込みキャッシングです。

・インターネット申込みで24時間全国受付

・お申込みはとっても簡単、お申込みフォームに入力するだけ。

・過去に自己破産・債務整理等された方もまずはお申込みください。

・大手消費者金融やカードローンの審査が通らなかった方もお申込みください。

・女性スタッフが対応致します。

10.来店不要・振込キャッシング【パーソナルクレジット セントラル】

<<創業40年を超える安心と実績の「セントラル」>>

WEB申込で当日最短融資可能です!

全国の皆さまからのお申込みに対応いたします。

セントラルは昭和48年創業の老舗の貸金業です。

全国に17店舗展開しております。 東京都内4店舗(浅草、新橋、新宿、池袋)、埼玉と神奈川に各1店舗 愛媛6店舗、香川2店舗、高知1店舗、岡山2店舗 計17店舗展開。

全国のセブン銀行ATM提携を開始し、 全国の方々にもますますご利用していただきやすくなりました。

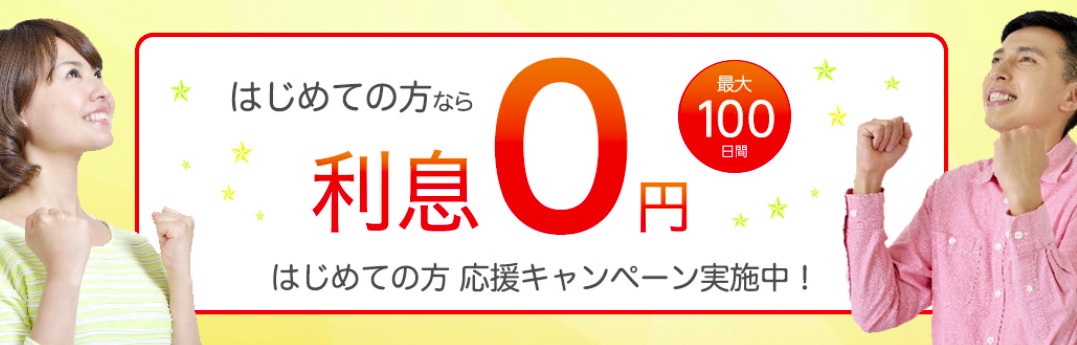

さらに、ご利用が初めての方は最大30日間金利0円!

11.安心できるパートナー【ハローハッピー】フリーローン

ハローハッピーは身近なキャッシング!

20歳以上で定期的に収入のある方を対象としております(パート・アルバイト・主婦の方も歓迎します)

家電ローン:家電製品のご購入

教育ローン:保育園〜大学の学費

リフォームローン:ご自宅の増改築・修理

医療ローン:入院、通院費 事業資金ローン

事業資金ローン:自営業、学資資金

ハローハッピーは各都道府県の方々へのサービスが手厚いお店です。

12.来店不要・振込キャッシング【女性専用 マイレディス】

<<創業40年を超える安心と実績の「セントラル」>>

そんなセントラルから生まれた女性専用のキャッシング【マイレディス】

WEB申込で当日最短融資可能です!

全国の皆さまからのお申込みに対応いたします。

中四国中心に店舗展開の老舗セントラルは、首都圏店舗も拡充中!

全国のセブン銀行ATM提携を開始し、 全国の方々にもますますご利用していただきやすくなりました。

さらに、ご利用が初めての方は最大30日間金利0円!

女性専用!在宅で稼ぐ【FANZAノンアダルトチャットレディ募集】

自分の好きなタイミングで稼げる在宅チャットレディ。

ノンアダルトだから安心、スマホで出来るかんたん在宅ワークです。

初めての方でも「業界最大手」「FANZAだから安心」してお仕事できます。

高収入在宅アルバイトならFANZAチャットガール!

隙間のお時間でお仕事可能、副業としても大歓迎です。

万全の個人情報管理、時給7,500円以上可、最短翌日振込!

佐世保の街金|サービス対象地域について

佐世保市にお住まいの方で、急な出費でお金が必要になった際、どこで借りれば良いか迷うことはありませんか?

銀行のカードローン以外にも、**街金(消費者金融)**という選択肢があります。

しかし、街金と一口に言っても、それぞれサービスを提供している地域が異なるってご存知でしたか?今回は、佐世保市における街金(消費者金融)のサービス対象地域について、掘り下げて解説していきます。

街金(消費者金融)の役割と地域性の重要性

街金(消費者金融)は、銀行よりも柔軟な審査で、比較的小額の融資をスピーディーに行うことを得意としています。多くの場合、保証人や担保は不要で、インターネット、電話、あるいは直接店舗での申し込みが可能です。

では、なぜ街金(消費者金融)には「サービス対象地域」というものが存在するのでしょうか。これにはいくつかの合理的な理由があります。

- 効率的な運営と顧客サポート: 物理的な店舗を構えている街金(消費者金融)の場合、その店舗から無理なくアクセスできる範囲をサービス対象とすることが効率的です。例えば、佐世保市内に拠点があれば、市内の顧客への迅速な対応や、万が一の際の訪問によるサポートなどもスムーズに行えます。地域を絞ることで、きめ細やかな顧客サービスを提供しやすくなるのです。

- 地域経済への理解と柔軟な審査: 特定の地域に特化することで、その地域の産業構造や住民の生活スタイル、さらには雇用状況などを深く理解することができます。これにより、大手金融機関では見過ごされがちな個別の事情も考慮に入れた、より柔軟な審査が可能になります。佐世保市特有の経済状況や住民の生活サイクルを理解している街金(消費者金融)であれば、より親身な融資相談に応じてくれるかもしれません。

- 法的要件とリスク管理: 貸金業法などの法令に基づき、貸金業者は営業所の所在地や営業範囲を明確に定める必要があります。これは、適正な事業運営を促し、利用者保護を強化するための重要な側面です。また、地域を限定することで、貸付リスクを管理しやすくなるという側面もあります。

このように、サービス対象地域は、街金(消費者金融)が効率的かつ適切に事業を行う上で非常に重要な要素なのです。佐世保市にお住まいのあなたが街金(消費者金融)の利用を検討するなら、まずご自身の居住地がその街金(消費者金融)のサービス対象地域に含まれているかを確認するのが、最初の、そして最も大切なステップとなるでしょう。

佐世保市内で多くの街金(消費者金融)が対象とするエリア

佐世保市は、広大な面積を持つ都市です。中心市街地から郊外、さらには離島まで多様な地域が存在します。街金(消費者金融)によってカバーする範囲は異なりますが、一般的に佐世保市内の以下の地域は、多くの街金(消費者金融)がサービス対象としている可能性が高いです。

- 市街地の中心部: 本島町、栄町、京町、湊町といった、佐世保市の行政機関や主要な商業施設が集まるエリアは、人口密度も高く、交通の便も非常に優れています。そのため、ほとんどの街金(消費者金融)が積極的にサービスを提供しています。利便性が高いため、利用者も集中しやすいエリアといえるでしょう。

- 主要な生活圏と住宅街: 大野町、早岐、日宇、三川内、広田など、佐世保市内でも特に人口が多く、学校、病院、スーパーなどの生活インフラが充実している地域は、安定した顧客基盤が見込めるため、多くの街金(消費者金融)が積極的にサービスを提供しています。

- 市街地近郊の地域: 相浦、小佐々、世知原、吉井など、中心部から少し離れるものの、一定の人口があり、地域コミュニティが形成されているエリアも、対象となることがあります。これらの地域は、市街地へのアクセスも比較的良好で、通勤・通学圏内にあることが多いです。

ただし、上記はあくまで一般的な傾向であり、個々の街金(消費者金融)の具体的なサービス対象地域は必ず確認するようにしてください。特に、佐世保市内の**離島(宇久島、黒島など)**にお住まいの方や、非常に山間部の過疎地域にお住まいの場合、利用できる街金(消費者金融)が限られる可能性があります。これは、物理的な距離や、万が一の際の訪問対応の難しさなどが影響するためです。オンラインで手続きが完結する街金(消費者金融)であれば、地理的な制約が比較的少ない場合もありますが、それでも最終的な審査では居住地情報が考慮されることは念頭に置いておきましょう。

あなたの地域が対象か?確実な確認方法

「私が住んでいる佐世保のこの場所は、本当に街金(消費者金融)のサービス対象なのだろうか?」と疑問に思った時は、以下の方法で確実に確認することができます。

- 街金(消費者金融)の公式サイトで情報を確認する: 多くの街金(消費者金融)は、公式サイト上に「お申し込みの流れ」や「よくあるご質問(FAQ)」のページなどでサービス対象地域を明記しています。中には、郵便番号や住所を入力するだけで、対象かどうかを自動で判定してくれる便利なシステムを備えているところもあります。これが最も手軽で、最初に試すべき方法です。

- 直接電話で問い合わせる: 最も確実な方法の一つです。街金(消費者金融)のカスタマーサービスや相談窓口に直接電話し、ご自身の住所を伝えてサービス対象かどうかを尋ねてみてください。もし、残念ながら対象外だったとしても、オンラインでの対応の可能性や、他の関連情報についてアドバイスをもらえるかもしれません。直接話すことで、より詳しい情報を得られるメリットもあります。

- オンライン申し込みフォームで試行する: 実際にオンラインで申し込みプロセスを進めてみるのも一つの方法です。多くの街金(消費者金融)の申し込みフォームでは、住所を入力する段階で「対象外の地域です」といったエラーメッセージが表示されることがあります。これは、その街金(消費者金融)があなたの地域をサービス対象としていないことを意味します。ただし、この方法は個人情報を提供することになるため、利用を検討している街金(消費者金融)が信頼できる正規の業者であることを、事前にしっかりと確認してから行ってください。

佐世保の地域性に合わせた街金(消費者金融)の選び方

佐世保市には、全国展開している大手街金(消費者金融)だけでなく、地域に根ざした中小の街金(消費者金融)も存在します。佐世保という土地柄を理解し、その特性に合わせたサービスを提供しているところを選ぶことは、あなたにとって大きなメリットをもたらすかもしれません。

例えば、地域密着型の街金(消費者金融)の中には、以下のような特徴を持つところがあるかもしれません。

- 地元経済への深い理解に基づく柔軟な審査: 佐世保は、造船業や米軍基地関連の産業、観光業など、独自の経済構造を持っています。地域密着型の街金(消費者金融)は、こうした地元の産業や、そこで働く人々の収入サイクル、あるいは個人事業主の事業特性などを深く理解し、画一的なシステム審査では見落とされがちな部分も考慮に入れた、柔軟な審査を行ってくれる可能性があります。

- 対面でのきめ細やかなサポート体制: インターネットでの手続きが主流となっている現代でも、「直接会って相談したい」「顔を見て話したい」というニーズは根強く存在します。佐世保市内に店舗を構える街金(消費者金融)であれば、こうしたニーズに応え、より親身な相談に乗ってくれるかもしれません。地域の顧客との信頼関係を重視する姿勢が見られることもあります。

- 地域貢献を通じた信頼関係の構築: 地域に根ざした街金(消費者金融)は、単に金融サービスを提供するだけでなく、地元の祭りやイベントへの協賛、地域活性化への貢献などを通じて、住民との信頼関係を築こうと努力していることがあります。

これらの地域性は、佐世保市に住むあなたが、より身近で親しみやすく、かつあなたの状況に合った街金(消費者金融)を見つける手助けになるかもしれません。ただし、情報が限られている場合もあるため、ご自身でしっかりと情報収集を行い、納得のいく選択をすることが大切です。

借り入れを検討する際の最終チェックポイント

佐世保市内の街金(消費者金融)のサービス対象地域であることを確認し、いざ借り入れを検討するとなったら、以下の点を必ず頭に入れて、慎重に進めてください。

- 正規の登録業者であるかを確認する: 何よりも重要なのがこの点です。「ブラックでもOK」「審査なし」といった甘い言葉で誘う違法な「闇金」には、絶対に手を出してはいけません。正規の街金(消費者金融)は、金融庁に登録されており、その情報は金融庁のウェブサイトで確認することができます。必ず事前に確認するようにしてください。

- 金利と返済総額を正確に把握する: 金利は年率で何%なのか、遅延損害金は発生するのかなど、金利に関する情報を詳しく確認しましょう。また、ご自身の現在の収入と支出を正確に把握し、無理のない返済計画を立てることが非常に大切ですし、毎月の返済額はいくらで、何回で完済するのかを明確にしておくべきです。

- 契約内容を隅々まで確認し理解する: 契約書にサインをする前に、必ず全ての内容を読み込み、理解できない点や疑問点があれば、その場で質問して明確にしてください。口頭での説明だけでなく、書面での確認を怠らないことが、後々のトラブルを防ぐ上で極めて重要です。

- 多重債務のリスクを十分に認識する: 複数の街金(消費者金融)から借り入れを重ねると、返済が困難になり、多重債務に陥るリスクが高まります。借り入れは計画的に行い、本当に必要な金額だけを借りるようにしてください。安易な借り入れは、自身の生活を苦しめる原因となります。

困った時の頼れる相談先

もし、借り入れや返済に関して不安なことや困ったことがあれば、一人で抱え込まずに専門機関に相談することも非常に大切です。

- 日本貸金業協会 貸金業相談・紛争解決センター: 貸金業に関する相談や苦情を受け付けている中立的な機関です。

- 法テラス(日本司法支援センター): 法律に関するトラブル全般について、情報提供や適切な相談窓口の紹介を行っています。多重債務に関する相談も受け付けています。

- 各自治体の消費者生活センター: 消費生活全般に関する相談を受け付けており、多重債務に関するアドバイスも提供しています。

これらの機関は、あなたの状況に合わせて適切なアドバイスやサポートを提供してくれます。

佐世保市で街金(消費者金融)の利用を検討する際は、これらの情報を参考に、ご自身の状況と照らし合わせながら慎重に判断してください。借り入れは、あなたの生活を支えるための一時的な手段であり、健全な金銭管理を心がけることが、より安定した未来へとつながるでしょう。

佐世保の街金!ブラックでも借りれるカードローンを探すときの注意点

急な出費やお金が必要な場面で、街金(消費者金融)の利用を検討する方も多いでしょう。

特に激甘審査を行っている街金があり、審査が通りやすいという特徴があります。

しかし、審査が甘いという点にばかり注目しすぎてしまうと、後々思わぬトラブルに巻き込まれる可能性もあります。

1. 審査の甘さだけで決めない

激甘審査を謳っている街金は、多くの借り手にとって魅力的に感じるかもしれません。

しかし、審査が緩いということには、裏にリスクが隠れていることもあります。

例えば、過去に金融事故を起こした人や、収入が不安定な人でも融資が通りやすいため、借りすぎて返済が困難になることが考えられます。

・審査基準が甘いため、借りやすくても返済が滞るリスクが高い。

・返済計画を立てずにお金を借りることで、長期的に困窮する可能性がある。

そのため、審査の甘さだけで街金を選ぶのではなく、返済能力をきちんと考慮した上で、自分の状況に合った業者を選ぶようにしましょう。

2. 高金利の可能性を忘れない

街金(消費者金融)の特徴的な部分は、その高金利です。

激甘審査を行っている業者では、金利が通常よりも高めに設定されていることが多く、借りたお金に対して支払う利息が予想以上に大きくなる場合があります。

特に、激甘審査の街金では、借り入れ額が大きくなると、その分利息が膨らむ可能性が高いです。

例えば、10万円を年利18%で借りた場合、1年後には1万8,000円の利息がかかります。もし元金が大きければ、さらに多額の利息を支払うことになります。

高金利の具体例

| 借入額 | 年利18% | 1年間の利息 | 返済総額 |

|---|---|---|---|

| 10万円 | 18% | 18,000円 | 118,000円 |

| 50万円 | 18% | 90,000円 | 590,000円 |

このように、金利の高さが負担となる場合があるため、借りる金額や返済期間を慎重に考慮することが重要です。

3. 利用条件や契約内容の確認

激甘審査を提供している街金に申し込む際、契約内容や利用条件についてもよく確認しておく必要があります。

中には「即日融資」を謳っている業者もありますが、急いで申し込む前に以下の点を必ずチェックしましょう。

- 金利や利息の詳細: 自分が借りる金額に対してどれくらいの金利が適用されるのかを確認します。年利だけでなく、日割り計算がどうなるかもチェックしましょう。

- 返済方法や期日: 返済が毎月一定額で済むのか、ボーナス返済が可能かどうかなどを確認し、自分に合った返済計画を立てます。

- 手数料や追加費用: 契約に含まれる手数料や追加費用があるかもしれません。これらが後々負担にならないよう、契約前に全て明確にしておきましょう。

契約書に不明点があれば、担当者に尋ねて理解を深めてから契約するようにしましょう。

確認を怠ると、後で意図しない費用が発生することがあります。

4. 返済計画をしっかりと立てる

街金(消費者金融)を利用する際には、返済計画をしっかりと立てることが非常に重要です。

特に激甘審査の業者では、必要以上にお金を借りてしまいがちですが、返済計画を立てずに借りると後で大きな負担がかかります。

返済計画を立てる際に考慮するべきポイントは以下の通りです。

- 収入とのバランス: 自分の月々の収入に見合った返済額を設定します。無理のない範囲で返済ができる額を選ぶことが大切です。

- 返済期限: 短期間で完済するのか、長期間で返済するのかを決めましょう。短期間で返済を終えることで、金利負担を減らすことができますが、その分毎月の返済額が増えます。

- ボーナス返済の活用: ボーナス時期に一括返済することで、金利負担を軽減できる場合があります。

しっかりとした返済計画を立てておくことで、返済期日を守りながら余計な利息を支払うことなく、完済まで進むことができます。

5. 不正業者を避ける

激甘審査の街金の中には、不正な営業を行っている業者も存在します。

これらの業者は、借り手を金利や手数料で搾取したり、契約内容が不明瞭だったりする場合があります。

特にインターネットで広告を見て申し込む場合、信頼性が不明な業者に騙されないように注意が必要です。

信頼できる街金(消費者金融)を選ぶためには、以下の点に注意しましょう。

- 業者の登録状況を確認: 信頼できる業者は、金融庁に登録された正規の業者です。業者の登録番号や営業許可証を確認しましょう。

- 評判や口コミをチェック: 他の利用者の評判や口コミを確認して、過去にトラブルがなかったかを調べてみましょう。

信頼できる業者を選ぶことが、最終的には無駄なリスクを回避することにつながります。

6. 複数の業者を比較検討する

街金(消費者金融)は多くの業者が存在しています。

激甘審査を謳っている業者もあれば、金利が低めで条件が良い業者もあります。

そのため、複数の業者を比較することで、自分に最適な業者を見つけることができます。

比較する際に注目すべき点は、以下の通りです。

- 金利の違い: 各業者の金利を比較し、少しでも低い金利で借りられる業者を選びます。

- 借入限度額: 借入限度額がどれくらいかも比較して、自分の借りたい金額に対応できる業者を選びましょう。

- サービス内容の違い: 即日融資や便利な返済方法など、サービス内容の違いも確認して、自分に合った業者を選びます。

複数の業者を比較することで、最も条件の良い業者を見つけることができます。

激甘審査の街金を利用する際には、金利や契約内容、返済計画をしっかりと確認することが大切です。

安易に借り過ぎず、返済が滞らないよう計画的に利用することが、後々のトラブルを避けるために重要です。

また、不正業者に騙されないよう、信頼できる業者を選ぶことを心がけましょう。

佐世保の街金!ブラックでも借りれるカードローンは審査が甘い

急にお金が必要なとき、街金(消費者金融)は便利な選択肢です。

街金は、銀行や大手消費者金融と比べて審査が甘いと評判です。

そのため、他の金融機関では融資が難しい場合でも、比較的簡単に融資を受けることができます。

しかし、「審査が甘い」ということは、他にも注意すべき点が多いということです。

街金とは何か?

まず、街金(消費者金融)とはどんな存在なのかを理解しておくことが大切です。

街金は、個人向けに少額の融資を行っている金融機関です。

融資額は一般的に数万円から数十万円程度と少額であり、急な資金需要に対応するために利用されます。例えば、急な病気や冠婚葬祭、生活費の不足などの際に便利です。

街金は、大手銀行や信販会社とは異なり、融資の審査基準が緩い傾向にあります。

これは、少額の融資が中心であるため、リスクを抑えるために柔軟な審査が行われるからです。しかし、審査基準が緩いと言っても、無計画に利用してしまうと、後々大きな負担になる可能性があることを理解しておきましょう。

街金が審査が甘い理由

街金が審査が甘い理由は、大きく分けて以下のポイントが挙げられます。

1. 融資額が少額だから

街金は、主に少額融資を提供しています。

このため、銀行や大手消費者金融に比べて審査基準が緩くなることがあります。

少額融資であれば、返済のリスクも少ないと見なされ、融資を受けやすくなるのです。例えば、数万円から十数万円程度の借入であれば、返済の目途が立ちやすいため、柔軟な審査が可能です。

2. 審査がスピーディーで簡単

街金では、融資の申込みから実際に融資を受けるまでの手続きが非常にスピーディーです。

一般的に、銀行や大手消費者金融では、審査に数日かかることもありますが、街金では最短で即日融資が可能です。

また、提出する書類も最低限で、手続きが簡単です。このように、時間的余裕がない方にとって非常に便利で、審査が甘いと感じる要因となっています。

3. 他社からの借り入れに対して寛容

銀行や大手消費者金融では、すでに他社から借り入れがある場合、審査が厳しくなることがあります。

しかし、街金は比較的他社からの借り入れに対して寛容です。

少額であれば、他社の借入状況に関わらず融資が通ることもあります。これは、リスクの少ない融資を提供することで、融資をスムーズに行うための一つの方針といえます。

街金の利用メリット

街金を利用することにはいくつかのメリットがあります。

急な支払いが必要な場合や予期しない支出に対して迅速に対応できる点が、最大の魅力です。

1. 即日融資の利用が可能

街金では、即日融資を行っているところも多く、急な支出に対応できます。

審査が早いため、申し込みから融資までの時間が短く、素早くお金を手に入れることができます。急にお金が必要になった場合でも、ほとんどのケースで当日中に融資を受けることが可能です。

2. 融資額が少額で安心

街金では、少額融資が中心となります。

例えば、5万円や10万円程度の借り入れであれば、短期間で返済することが可能です。少額であれば、利息の負担も軽く、借入額が大きく膨らむリスクが少ないため、利用しやすいです。

3. 簡単な手続き

街金での融資手続きは、比較的簡単であることが多いです。

インターネットから申し込むことができ、必要書類も少なく、審査も早いので、時間がないときにも便利です。これにより、普段忙しくて銀行に行けない人でも気軽に利用できます。

街金を利用する際の注意点

審査が甘いという点で街金は非常に魅力的ですが、利用する際にはいくつか注意点もあります。

メリットだけではなく、デメリットもしっかり理解しておくことが大切です。

1. 高い金利

街金の金利は、他の金融機関に比べて高い傾向にあります。

例えば、年率20%以上になることもあり、返済額が膨らむ可能性があります。短期間で返済すれば問題ありませんが、返済が遅れると利息が膨れ上がるため、借入額を無駄に増やさないように注意が必要です。

2. 借り過ぎに注意

街金の審査は甘いからといって、つい借り過ぎてしまうことがあります。

少額融資でも、借り過ぎると返済が厳しくなり、最終的に借金が膨らむ可能性があります。無理なく返済できる金額を借りるようにしましょう。

3. 利用計画を立てる

急な資金調達が必要な場合でも、街金を利用する前にしっかりと返済計画を立てることが大切です。

利用する金額、返済の期日をしっかりと把握し、無理のない返済計画を立てることが、後々の負担を減らすために重要です。

佐世保の街金!ブラックでも借りれるカードローン|総量規制オーバーでも借りれるか?

街金(消費者金融)は、「激甘審査」という言葉でよく知られています。

他の金融機関では融資を受けることが難しい人でも、街金ではお金を借りられることがあります。

これは、比較的審査が緩く、柔軟な対応をしてくれることが要因です。

しかし、街金でも気をつけなければならないルールがあります。それが「総量規制」です。では、もし総量規制を超えてしまった場合、激甘審査の街金でお金を借りることはできるのでしょうか?

1. 総量規制の基本

総量規制は、消費者金融が融資を行う際に遵守しなければならない法律です。

具体的には、個人が借り入れられる金額は、年収の3分の1までと定められています。これは、過剰な借り入れを防ぐために作られた規制で、借り手が返済能力を超えて借り入れをしないようにするためのものです。

例えば、年収300万円の人が借り入れを希望する場合、最大で100万円までしか融資を受けることができません。この規制は、消費者金融にとっては守らなければならないルールであり、規制を超えて融資をすることはできません。

2. 街金(消費者金融)の激甘審査

限らず、街金(消費者金融)は、他の金融機関よりも審査が柔軟であることが特徴です。

具体的には、クレジットヒストリーに問題があっても審査に通る可能性が高く、収入が不安定な人でも融資を受けられることがあります。

街金の特徴

- 柔軟な審査: 信用情報が悪くても借りられる場合がある。

- 少額融資対応: 必要最低限の金額だけ借りることができる。

- 迅速な融資実行: 急ぎの資金調達が可能。

街金の「激甘審査」と言われる理由は、このような特徴から来ており、どうしてもお金が必要な人にとっては非常に有用な存在となっています。

3. 総量規制オーバーでも借りられる可能性はあるのか?

では、総量規制を超えてしまった場合、街金で借りられるのでしょうか?

基本的には、総量規制を超える融資はできませんが、以下の方法で解決できる場合があります。

3.1 配偶者の収入を合算する

総量規制は、借り手本人の年収の3分の1を超える借り入れを制限します。

しかし、配偶者がいる場合、その配偶者の年収を合算することが可能です。例えば、年収300万円の本人と年収400万円の配偶者がいれば、合計700万円となり、最大で233万円まで借り入れが可能です。これによって、規制を超えて融資を受けられる可能性があります。

3.2 他社での借り入れを整理する

もし他の消費者金融から多くの借り入れがある場合、その借り入れを一旦整理することで、新たに融資を受けることが可能になります。

借り換えローンを利用して、複数の借り入れを一本化し、金利を下げることもできます。その結果、総量規制を守る範囲内で新たな借り入れを行うことが可能になります。

3.3 少額の融資を受ける

規制を守るためには、少額の融資を希望することが重要です。

例えば、数万円程度の融資を希望する場合、総量規制内であれば問題なく融資が受けられることが多いです。街金では、少額の借り入れにも柔軟に対応しており、その範囲内で融資を受けることができる場合もあります。

3.4 利用目的を正当化する

街金では、融資を希望する理由を説明することで、審査が有利に進むことがあります。

例えば、事業資金や急な医療費など、正当な理由がある場合、総量規制を厳格に適用しないことがあります。審査担当者によっては、柔軟に対応してくれる場合もありますので、融資の目的を明確に伝えることは有効な手段となります。

4. 街金で借りるために知っておくべきこと

街金を利用する際には、いくつか注意点があります。

特に、総量規制を超える場合は慎重に行動する必要があります。

- 返済計画を立てる: 融資を受けた場合、返済計画をしっかり立てることが重要です。返済能力を超える借り入れをしてしまうと、後々の返済が厳しくなり、信用情報にも悪影響を与える可能性があります。

- 高額な借り入れは避ける: 総量規制を守るためには、無理に高額な融資を受けることは避け、必要最低限の金額を借りることをおすすめします。

- 審査の詳細を確認する: 街金の審査は柔軟ですが、どこまで対応してくれるのかは事前に確認することが大切です。特に、規制を超えて融資を受けるためには、さまざまな条件をクリアする必要があります。

佐世保の街金!ブラックでも借りれるカードローン|即日融資を受けるには

急にお金が必要な場面は、誰にでも訪れることがあります。

特に、予期しない支払いが発生したときや急な用事でお金を借りる必要が出てきたとき、街金(消費者金融)の即日融資が便利です。

「激甘審査」の街金も存在し、柔軟に対応してくれるため、融資を受けやすい環境が整っています。そこで、即日融資を受けるために必要なステップや注意点について、わかりやすく解説します。

1. 即日融資を受けるための基本的な流れ

即日融資を受けるためには、ある程度の準備が必要です。

街金で即日融資を受けるには、下記のような流れを踏むことが一般的です。

1.1 申し込みの際に必要な書類を準備

まず最初に、申し込みの際に必要な書類を用意することが大切です。

街金によって必要書類は若干異なりますが、一般的には以下のものが求められます。

- 本人確認書類(運転免許証、マイナンバーカード、パスポートなど)

- 収入証明書(給与明細書、源泉徴収票、確定申告書など)

- 住所確認書類(公共料金の請求書、住民票など)

これらの書類を事前に整えておくと、申し込みから審査までの時間を短縮できます。

1.2 申し込みを行う

書類を準備したら、次に申し込みを行います。

多くの街金では、オンライン申し込みを受け付けており、自宅や外出先からでも手軽に申し込むことができます。

特に即日融資を希望する場合、迅速に申し込むことが重要です。

オンラインで申し込む際、必要事項(名前、住所、電話番号、勤務先、年収など)を入力し、上記の書類をアップロードします。申し込みが完了したら、審査が開始されます。

1.3 審査を通過し、契約

申し込みが完了すると、街金は提出された情報を基に審査を行います。

即日融資を受けるためには、この審査をスムーズに通過することが求められます。審査には通常、数分から数時間かかることがありますが、街金によっては早ければ数分で結果が出ることもあります。

審査が通過した場合、契約が締結されます。契約書を確認し、サインをした後、融資金が指定した口座に振り込まれます。

1.4 即日融資を受ける

契約が完了したら、振込手続きが行われ、即日融資を受けることができます。

振込時間は街金によって異なりますが、営業終了前に申し込みを完了していれば、その日のうちに振り込まれることがほとんどです。

2. 即日融資を受けるためのポイント

即日融資を受けるためには、いくつかのポイントを押さえておくことが重要です。

2.1 申し込み時間を確認する

即日融資を受けるためには、申し込みを完了する時間が非常に重要です。

多くの街金では営業時間内に申し込むことで、当日中に融資を受けることができます。申し込み時間が遅くなると、その日のうちに融資を受けられないこともあるため、余裕を持って申し込むことをおすすめします。

2.2 収入証明をしっかりと準備

収入証明は、審査において非常に重要な要素となります。

収入証明が不十分だと、融資が受けられない可能性があります。正確な収入証明書を提出することで、スムーズに審査を通過しやすくなります。

2.3 返済能力を確認する

街金の審査基準には、返済能力も大きな要素として影響します。

即日融資を受けた後の返済が可能かどうかも、審査のポイントとなります。自分の返済能力をしっかりと把握し、過剰な借入を避けることが大切です。

3. 即日融資が受けられる激甘審査の街金

審査が比較的甘い街金が多数存在しています。

これらの街金では、柔軟な審査基準を採用しており、過去に延滞歴があったり、少し収入が不安定だったりしても融資を受けやすいことが特徴です。

3.1 柔軟な審査

激甘審査の街金は、一般的な消費者金融に比べて審査基準が柔軟で、申し込み者の状況をしっかりと考慮して融資を行うことが多いです。

信用情報に問題があっても、安定した収入があれば融資を受けることができる場合があります。

3.2 迅速な対応

街金では、迅速に対応してくれるところが多く、即日融資を希望する場合にも、できるだけ早く対応してくれる街金を選ぶことが大切です。

オンライン申し込みの際には、対応時間を事前に確認しておきましょう。

3.3 相談できるサポート体制

急にお金が必要になった場合、街金のスタッフに相談することで、最適な融資額や返済プランを提案してもらえることがあります。

自分一人で判断するのが不安な場合、しっかりとサポートを受けることができます。

4. 注意点

即日融資を受ける際には、いくつか注意しておくべき点があります。

特に、契約内容や金利に関しては事前にしっかり確認しておくことが大切です。

4.1 金利や手数料を確認

街金によっては、金利や手数料が高めに設定されている場合があります。

即日融資を受ける際には、金利や手数料についてしっかりと確認し、返済時の負担が大きくならないようにしましょう。

4.2 返済計画を立てる

融資を受けた後は、しっかりとした返済計画を立てることが重要です。

返済が遅れると、延滞金や信用情報に悪影響を与える可能性があります。返済額や期日をしっかりと守るよう心掛けましょう。

佐世保の街金!ブラックでも借りれるカードローン|闇金との違い

多くの街金(消費者金融)があり、急な資金が必要なときに助けてくれる存在となっています。

しかし、街金と一部で「闇金」と呼ばれる違法な貸金業者には、さまざまな違いがあります。どちらを選ぶかによって、その後の生活に大きな影響を与えることになるため、両者の違いをしっかりと理解することが大切です。今回は、街金と闇金の違いについて詳しく解説していきます。

街金(消費者金融)とは?

まず、街金とは何かを理解することから始めましょう。

街金(消費者金融)は、貸金業法に基づき正規に営業している金融業者です。街金は、一般的に金利や貸し出し条件が設定されており、法律に則って融資を行っています。も数多くの街金があり、急な資金調達を必要とする人々にとって重要な選択肢となっています。

1.1 街金の特徴と審査基準

街金の特徴として、比較的審査が柔軟であることが挙げられます。

一般的な銀行融資と比べると、融資の審査基準が緩やかで、過去にクレジットカードの遅延履歴があっても、一定の収入があれば融資を受けられる可能性があります。

また、申込みから融資までのスピードが速く、即日融資を受けられる場合もあります。これにより、急な出費に困っている方にとって非常に便利な存在です。

街金の審査基準は通常、収入の安定性や他の借り入れの状況を考慮します。

そのため、収入証明書や身分証明書が求められますが、基本的には正規の手続きに則った形で融資を受けることができます。審査が通るためには、自己破産をしていないことや一定の収入が求められることが一般的です。

1.2 法律に基づく金利と返済計画

街金は法律で金利の上限が定められています。

一般的に消費者金融の金利は年利15%〜20%程度であり、返済計画も契約書に記載された通りに進行します。

返済期限や金利については契約時に明確に確認され、借り手は自分の返済計画を立てることが可能です。返済が難しくなった場合、分割払いに応じてくれる場合もあります。

闇金とは?

一方で、闇金は完全に違法に営業している貸金業者です。

これらの業者は、法律を無視して高額な金利を設定し、法外な利息を取ることが特徴です。

闇金は、表向きは正規の金融業者を装っていますが、実際には融資契約において不正行為を行ったり、暴力的な取り立てをしたりすることがあります。

2.1 闇金の特徴と金利

闇金の最も大きな特徴は、金利が非常に高いことです。

法定金利が上限であるにも関わらず、闇金業者は年利100%を超える金利を設定することが一般的です。このような高金利のため、借りたお金が短期間で膨れ上がり、返済が不可能な状態に追い込まれることがあります。

金利が高いだけでなく、返済期限も短く、借り手に厳しい条件を突きつけることがあります。これにより、借り手は返済ができず、次々と新たな借金を重ねることになり、最終的に借金地獄に陥るケースが少なくありません。

2.2 闇金の取り立てとリスク

闇金の取り立て方法は非常に暴力的で、脅迫や嫌がらせ、さらには家族や友人にまで迷惑をかけることもあります。

返済が遅れると、業者から激しい取り立てが始まり、最悪の場合、命の危険を感じるような状況に陥ることもあります。

闇金は、借り手が返済を滞らせると、物理的な暴力や精神的な圧力をかけてくることがあり、借り手にとって非常に危険な存在となります。

このような取り立てを受けると、借り手の生活が破綻し、社会的にも追い込まれる可能性があります。

街金と闇金の違い

街金と闇金には、明確な違いがあります。

どちらもお金を貸すという点では同じですが、その運営方法や融資条件、借り手への対応が大きく異なります。

以下に、街金と闇金の主な違いをまとめました。

| 項目 | 街金(消費者金融) | 闇金 |

|---|---|---|

| 合法性 | 法律に基づく営業 | 違法な営業 |

| 金利 | 法定金利(年利15〜20%程度) | 高金利(年利100%以上) |

| 審査基準 | 安定した収入や信用を基に審査 | 審査がほとんどない |

| 返済計画 | 明確で計画的 | 無計画で強引な返済要求 |

| 取り立て方法 | 法的手続きに基づく | 暴力的・脅迫的な取り立て |

| 借り手の保護 | 法律で守られている | 保護されない |

街金を利用する際の注意点

街金を利用する際は、契約内容をしっかりと確認することが最も重要です。

特に、金利や返済期限については、事前に確認し、無理な借り入れを避けるようにしましょう。

また、借りすぎには注意が必要で、返済能力を超える額を借りることは避けるべきです。

万が一、返済が難しくなった場合には、無理に隠れて返済を続けるのではなく、早期に業者と相談し、返済計画を見直すことが大切です。

多くの街金では、返済条件の変更に応じてくれる場合もありますので、困った時は適切に対応しましょう。

佐世保の街金!ブラックでも借りれるカードローンで審査落ち・・お金を借りれないときは

数多くの街金(消費者金融)が存在しており、これらは一般的に「激甘審査」として知られています。

つまり、他の金融機関よりも比較的簡単にお金を借りられることが特徴です。

しかし、すべての申込者が審査に通るわけではなく、審査落ちすることもあります。

では、審査に落ちた場合はどうすればよいのでしょうか?

1. 街金(消費者金融)の審査に落ちる理由

まず、なぜ街金の審査に落ちるのかを理解することが重要です。

審査が甘いとはいえ、審査基準はしっかりとあります。そのため、いくつかの理由で審査に通らないことがあります。

1.1 過去の返済履歴に問題がある

街金の審査で最も重視されるのは「信用情報」です。

過去にクレジットカードの支払い遅延や、他の借入金の返済が滞った場合、それが信用情報に記録され、審査に大きな影響を与えます。

信用情報に傷がついていると、審査に通る可能性が大幅に下がります。

1.2 収入が安定していない

安定した収入がないと、返済能力が低いとみなされてしまいます。

たとえば、アルバイトや派遣社員の場合、正社員と比べて収入が不安定と判断されることがあります。

収入証明書を提出しても、その金額が不安定であったり、極端に少なかったりすると、審査が通りにくくなります。

1.3 他社からの借り入れが多い

すでに他社から複数の借り入れがあり、返済負担が大きい場合、新たな借入れを認められないことがあります。

借り入れ件数が多かったり、返済額が高かったりすると、街金側は「返済能力が不足している」と判断し、審査を通さないことがあります。

1.4 必要書類の不備

申請時に提出した必要書類に不備があった場合、審査に通らないことがあります。

たとえば、収入証明書が不完全だったり、本人確認書類が不正確であったりする場合です。

書類の不備があると、審査が遅れるだけでなく、最終的に審査に落ちる原因になることがあります。

2. 審査に落ちた場合の対処方法

審査に落ちた理由がわかれば、その後の対処法も見えてきます。

もし審査に通らなかった場合、どのような対応を取るべきか、いくつかの方法を考えてみましょう。

2.1 信用情報をチェックする

まず、最初にすべきことは自分の信用情報をチェックすることです。

信用情報には、過去の借入れや返済履歴が記録されています。

もし、過去に遅延や滞納があった場合、それが記録として残っている可能性があります。日本には「CIC」「JICC」「全銀協」といった信用情報機関があり、自分の信用情報を確認することができます。信用情報に問題があった場合は、その情報を修正してもらうことができる場合もあります。

2.2 収入証明を見直す

収入に不安がある場合、収入証明を見直してみましょう。

給与明細書や確定申告書を正確に提出することが重要です。また、もし収入が不安定な場合は、安定した職業に就くことを検討することも一つの方法です。アルバイトや派遣社員の場合でも、長期間にわたる安定した収入がある場合は、審査に通る可能性が高まります。

2.3 借金の整理をする

すでに他社から多く借り入れている場合、その借金を整理する方法もあります。

借り換えを検討することで、複数の借り入れを一本化し、月々の返済額を軽減することができます。また、返済が進んでいる借金を減らしていくことで、返済能力が高まります。返済負担が減れば、再度街金の審査を受ける際に有利になるでしょう。

2.4 必要書類の再提出

もし審査に落ちた理由が書類不備であった場合、すぐに必要書類を再提出しましょう。

申請時に提出した書類に不備があった場合、それが原因で審査に落ちてしまうことがあります。必要な書類を再度確認し、正確に提出することが大切です。

3. 審査に通らなかった場合の代替手段

もし街金(消費者金融)の審査に通らなかった場合、他にお金を借りる方法もいくつかあります。

ここでは、代替手段についていくつかご紹介します。

3.1 銀行カードローンを利用する

銀行カードローンは、金利が低く、借り入れ条件も比較的緩いことが特徴です。

街金よりも審査基準が厳しくなることがありますが、金利が低いため、借りたお金の返済が楽になることが多いです。街金の審査に落ちた場合でも、銀行カードローンの審査に通る可能性もあります。

3.2 質屋を利用する

物品を担保にしてお金を借りる方法として、質屋を利用することもできます。

金やブランド品、時計など、価値のある物品を担保にすることで、信用情報に影響を受けることなくお金を借りることができます。ただし、担保が返済できなかった場合に失われるリスクもあるため、慎重に検討することが大切です。

3.3 親や友人に頼む

もし身近に信頼できる親や友人がいる場合、借り入れを頼むことも一つの方法です。

ただし、お金の貸し借りは関係に影響を与えることがありますので、返済計画をしっかりと立て、相手に負担をかけないようにしましょう。

3.4 クレジットカードのキャッシング

クレジットカードにキャッシング機能がついている場合、カードを使ってお金を借りることができます。

これは街金よりも金利が高いことが多いため、早期に返済することが重要です。急な支払いが必要な場合には便利な手段となります。

激甘審査の街金で審査に落ちてしまった場合、原因を突き止め、改善策を取ることが重要です。

信用情報や収入の見直し、必要書類の確認を行い、再度申請を行うことができます。

また、他の金融手段を活用する方法も検討して、最適な方法でお金を調達できるようにしましょう。